Superfinishing for your lathes

Increase the cost-effectiveness of your carrier machine!

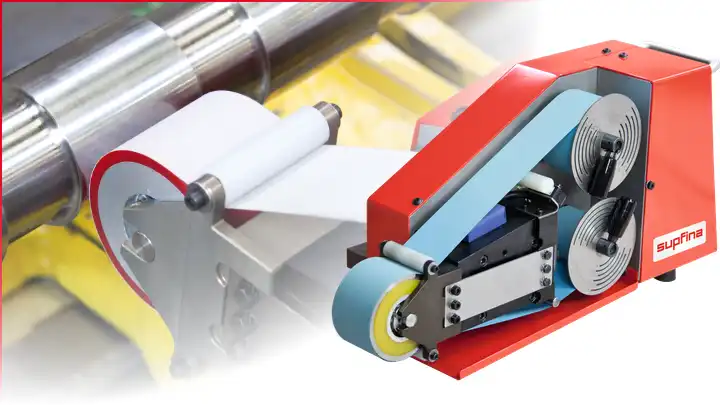

Ra < 0.05 µm with Superfinish attachments

Superfinishing – also known as Microfinishing or short-stroke honing – ensures perfect surface quality and maximum process reliability, with our attachments directly on your existing machine.

Whether you have a lathe, grinding machine, or other host machine, our attachments can be flexibly integrated into both conventional and CNC-controlled systems.

Perfect your workpieces and secure a decisive competitive edge!

What is the difference between this and conventional grinding or turning?

|

Verfahren |

Turning |

Schleifen |

Superfinish |

|

Oberfläche (Ra) |

~0,8 – 1,6 µm |

~0,2 – 0,4 µm |

< 0,05 µm |

| Material removal |

High |

Moderate |

Precision 1-3 µm |

|

Length of proceedings |

Fast |

Moderate |

Fast |

|

Post-processing required? |

Yes |

Potentially |

None |

With Supfina, you can get the most out of your existing technology—without any costly investments.

Experience superfinishing live – right at your location!

We bring our technology directly to you! With our specially equipped roadshow, we visit interested manufacturing companies throughout Europe.

You can experience our attachments live in action – practical, individual, and without obligation.

For each type of processing

More than 10,000 devices in use

Our Superfinish attachments can be quickly and easily mounted on your grinding and turning machines. Offer your customers the highest surface quality and increase your competitiveness.

We provide comprehensive advice: from selecting the right attachment and the ideal abrasives to precise process parameters – everything tailored to your requirements.

- Wide range of attachments

- Stone, tape, and hybrid devices

- Add-on to existing CNC, grinding, or turning machines

- Flexible and universally applicable

- Sophisticated and proven technology

- Low investment costs

- High economic efficiency

Workpieces

Which workpieces are suitable?

Whether shafts, sleeves, valve bodies, pistons, or sealing surfaces—our attachments are versatile. From individual parts to series production, they improve the surface quality of rotationally symmetrical components—directly on your machine.

News Supfina One

The smart Supfina One

Perfect for Superfinishing with Stone or Tape

Meet the new Supfina One — the perfect solution for manufacturers who want the benefits of superfinishing without the bulk, cost, or complexity of a custom machine. Designed specifically for small to medium production runs, the Supfina One delivers precision fine-finishing with impressive efficiency and minimal floor space requirements.

Its intelligent design, intuitive touchscreen controls, and flexible configuration options make it ideal for contract shops and production lines alike. Whether you’re looking for a cost-effective entry into superfinishing or a compact system that integrates seamlessly into your workflow, the Supfina One is built to fit your needs.

- Optimized for the Supfina Tape Finishing Attachment 210

- Perfect for small to medium batch sizes

- Affordable entry into precision finishing

- Compact footprint for easy integration

- Forklift-ready stand for effortless relocation

- Simple, intuitive touchscreen operation

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

Rental equipment

Flexible rental of attachments

Would you like to test our technology in your own process first or respond to production peaks at short notice?

No problem: our Superfinish attachments are also available as a rental solution – simple, fast, and without any investment risk.

- No investment required in advance

Perfect for pilot projects or custom jobs - Practical test without risk

Directly on your machine, with your component - Full cost control

Cost-effective rental models, no long-term commitment - Purchase with credit

Depending on individual device utilization and condition, purchase possible - Gaining initial experience

Regarding process parameters, surface quality and machining effort – directly transferable to subsequent series production

Get in touch with us!

Our contact form

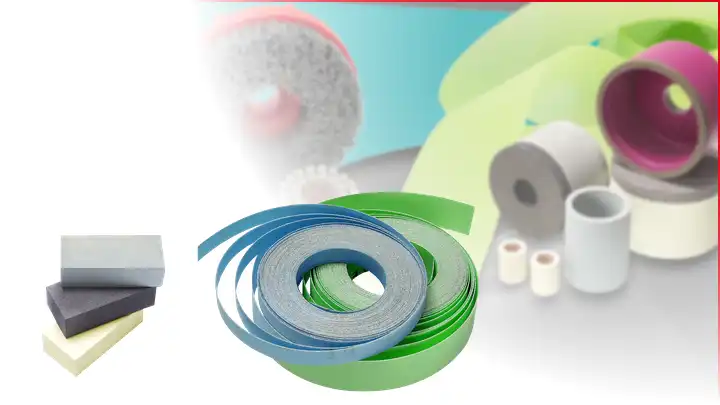

Tools for the highest quality

Offering the optimal superfinishing tools means being able to assess their quality.

All Supfina tools are characterized by consistently high quality and particularly long service life.

Less downtime, less scrap, no adjustment of machining parameters: this increases the cost-effectiveness and reliability of your machining process.

Always the latest news. Find out more in the News section.

Supfina Roadshow 2025 – Experience Superfinishing Attachments live!

We bring precision to you.

The time is almost here: starting in September, our roadshow vehicle will be touring Germany, Austria, and Switzerland—and it will be stopping at your location too! Experience our Superfinish attachments in real-life use directly in our roadshow vehicle.

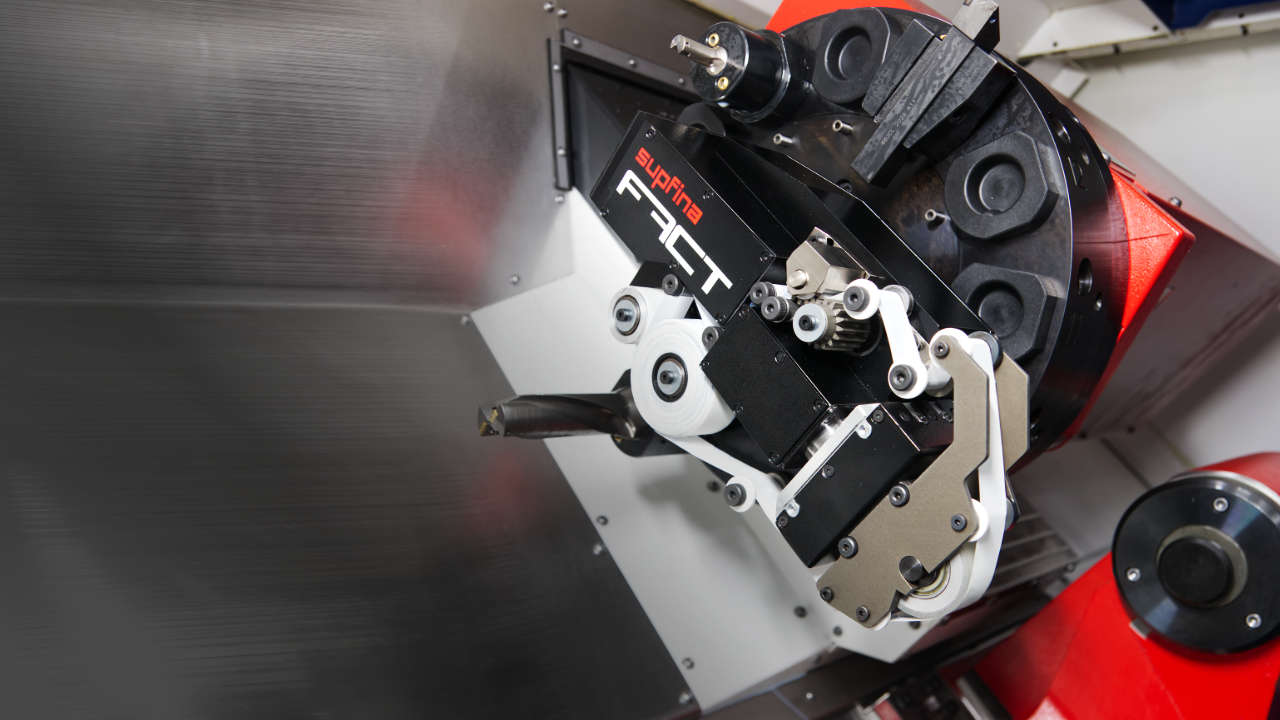

Supfina Fact: Specially designed for your CNC lathe

Our world first: the Supfina Fact. It is a compact belt finishing attachment, specially developed for mounting on turret lathes.

Deutsch

Deutsch