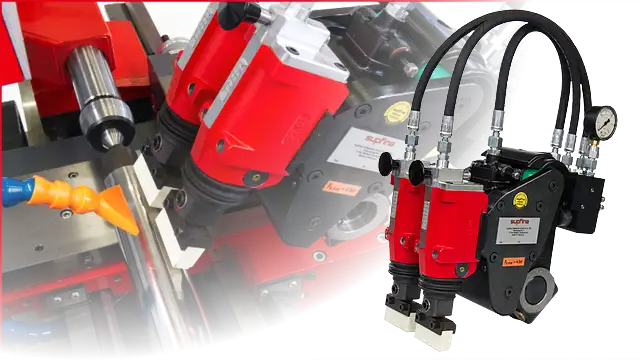

Pneumatic finishing device for installation on small, medium and large carrier machines for superfinishing of ground and finely turned surfaces.

Especially for narrow bearing seats between high bundles and workpiece bundles with small free stitches.

In addition to rotationally symmetrical shapes, flat and slightly concave or convex surfaces can also be processed..

| Technical data | Supfina 100 |

| Frequency DH/min, max / min | 5100 / 3300 |

| Amplitude in mm | ± 0.35 – 0.4 |

| Air pressure in bar | 4.5 |

| Air Consumption in Nm³/h | 6 – 7 |

| Weight in kg | 11.0 |

| Stone Guide Type | 21.01 |

| Stone Guide Stroke in mm | 25 |

| Stone Guide Quantity | 1 |

| Piston area in cm² | 7 |

Documentation and videos

Get smarter – connect with us

Thanks for your interest in our solutions!Let’s get to know each other. Continue to download... ×

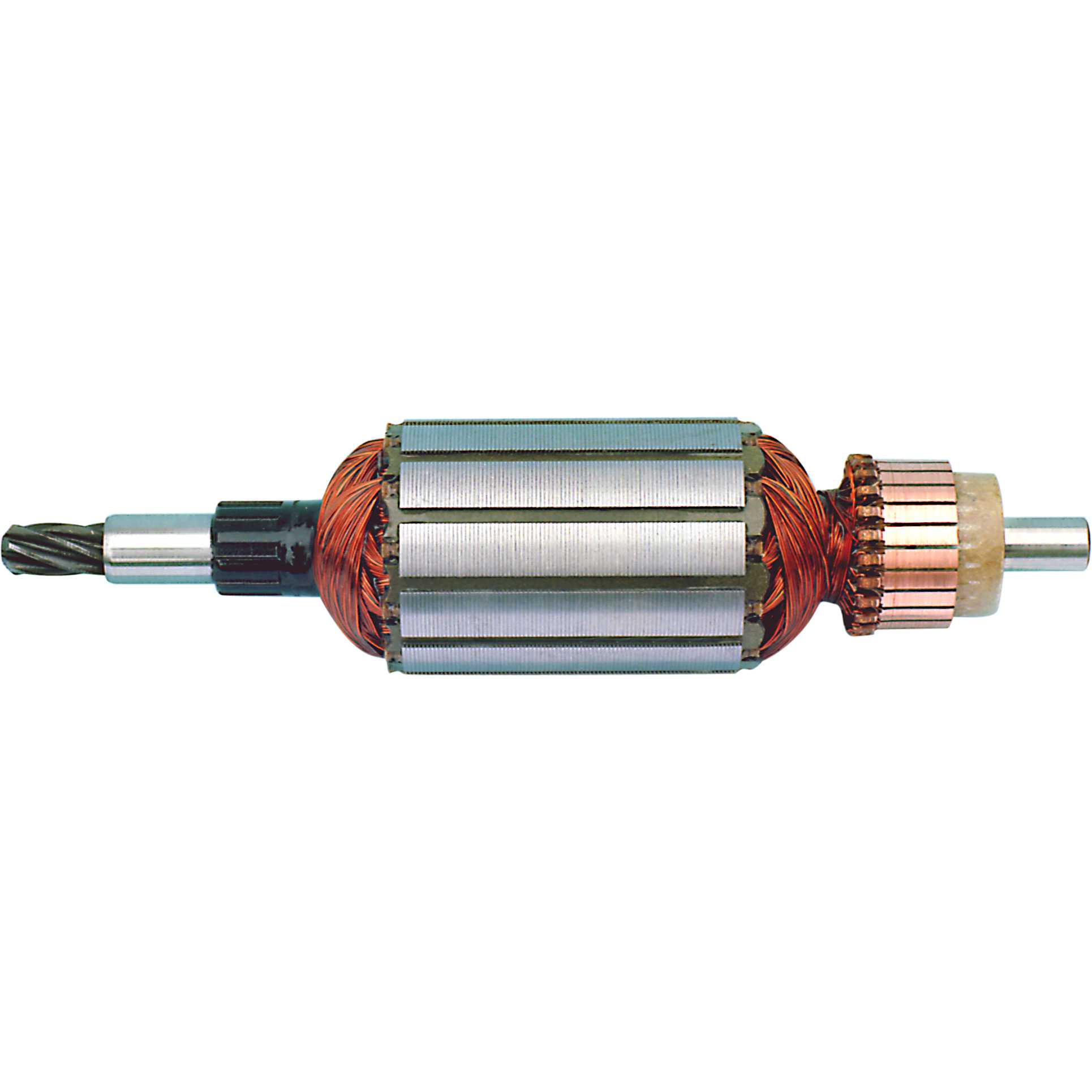

Typical workpieces for this attachment

Simply select the workpiece to be machined or a similar one and receive a customized selection of suitable Supfina attachments.

Quick, easy, and precise.

Cup tappet

The superfinishing of the surface at the cup tappet is very important to ensure optimal performance, durability and reliability of the engine.

Balance shaft

The bearings on the balancer shaft must be superfinished to reduce friction and wear, minimize noise, ensure precise alignment and increase durability. This improves the performance and efficiency of the engine.

Planetary gear

The front face of the planetary gear is finished to ensure precise alignment, minimized imbalance, increased durability, and reduced friction in the planetary gear system.

Crank shaft

For repairs and tuning, the bearing points of the crankshaft can be machined with superfinishing attachments. This can achieve surfaces like OEM or even better.

Pinion Shaft

The bearing points of the pinion shaft are exposed to particular loads. Therefore, these must be superfinished for a long running time.

Ball pin

Both the running surfaces and the ball surfaces must be finished. Supfina offers exactly fitting superfinishing attachments and tools.

Turbine shaft

The bearing seats of the turbine shaft can be machined with stone or tape finish as required. For lathes, carrier machines or in a turret, Supfina offers a suitable device.

Deutsch

Deutsch