Depending on the application, rollers in a wide variety of lengths and diameters require very low surface roughness up to mirror high gloss finish. Exactly the right field of application for superfinishing attachments and tools from Supfina.

Depending on the application, rollers in a wide variety of lengths and diameters require very low surface roughness up to mirror high gloss finish. Exactly the right field of application for superfinishing attachments and tools from Supfina.

Depending on the application, rollers in a wide variety of lengths and diameters require very low surface roughness up to mirror high gloss finish. Exactly the right field of application for superfinishing attachments and tools from Supfina.

Depending on the application, rollers in a wide variety of lengths and diameters require very low surface roughness up to mirror high gloss finish. Exactly the right field of application for superfinishing attachments and tools from Supfina.

Superfinishing the eccentric surfaces and the bearing points is crucial to ensure low-friction operation and a long component service life.

In production and repairs, superfinishing attachments can be used to process the surfaces. Friction, wear reduction, and sealing quality are important functions of the superfinish surface.

The bearing points of the pump shaft can be machined with stone or tape finish as required. For lathes, carrier machines or in a turret, Supfina offers a suitable device.

The bearing seats of the turbine shaft can be machined with stone or tape finish as required. For lathes, carrier machines or in a turret, Supfina offers a suitable device.

The outer surface of the sleeve is superfinished to increase the contact ratio of the guideway, thus making the sleeve more durable and precise. Superfinishing offers advantages, regardless of whether the sleeve is mounted in a ball bushing or sliding guide bush.

The bearing seats of the drive shaft are finished to enable precise and low-friction movement of the shaft in the bearing. For both carrier machines, lathes and turret lathes, Supfina offers a suitable attachment here.

The bearing seats of the gear shaft are finished to allow precise and low-friction movement of the shaft in the bearing. For both carrier machines, lathes and turret lathes, Supfina offers the suitable attachment here.

The main shaft is a critical component in many mechanical systems because it enables energy transmission and conversion, supporting a wide range of applications in various industries. The superfinishing surface of the bearing position determines long running time and low friction operation.

Piston pins allow the piston to move in the cylinder and transmit the compression torque generated by combustion to the connecting rod. In order to withstand the enormous loads over a long service life, a superfinished surface is necessary.

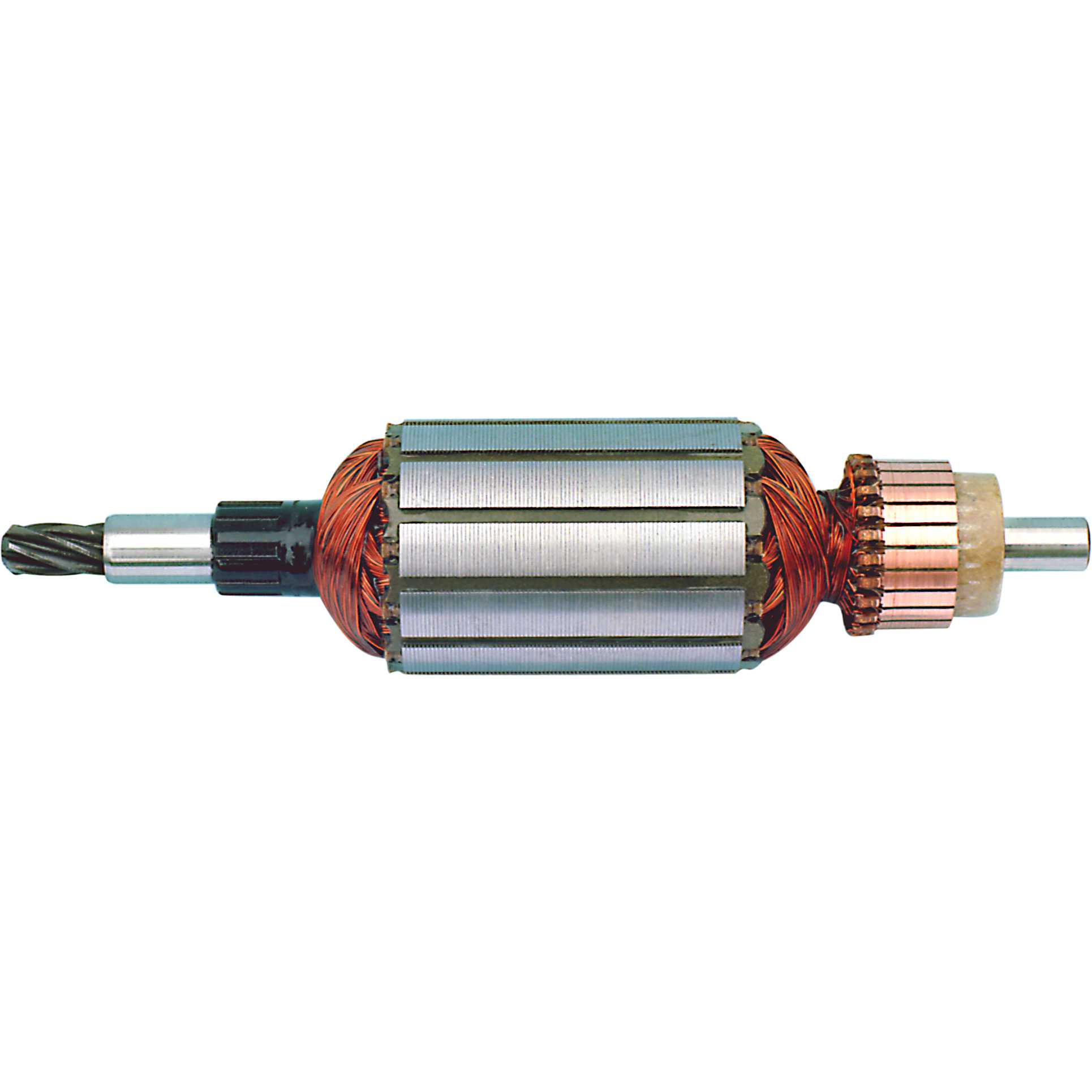

Superfinishing the bearing seats on the electric motor axis ensures low friction and precise movement of the rotor in the stator. Supfina supplies the appropriate attachments to produce this finish.

Supfina Grieshaber GmbH & Co. KG

Schmelzegrün 7

77709 Wolfach / Germany

+49 7834 866-0

info@supfina.com

www.supfina.com

Deutsch

Deutsch